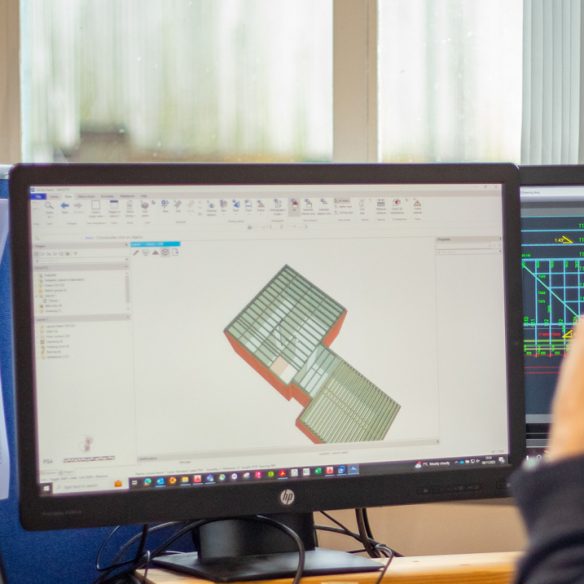

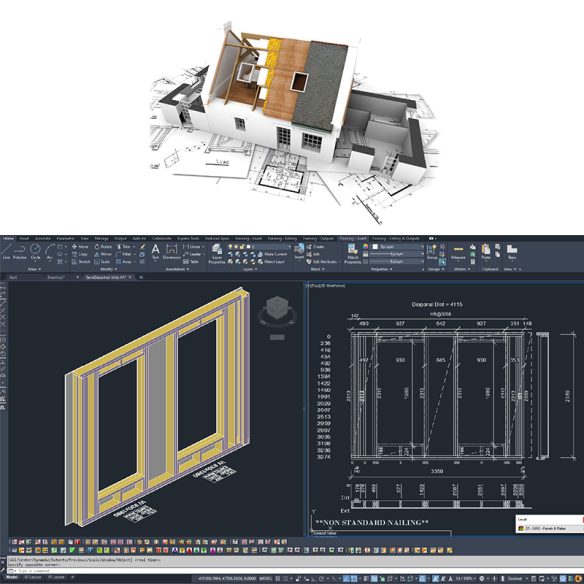

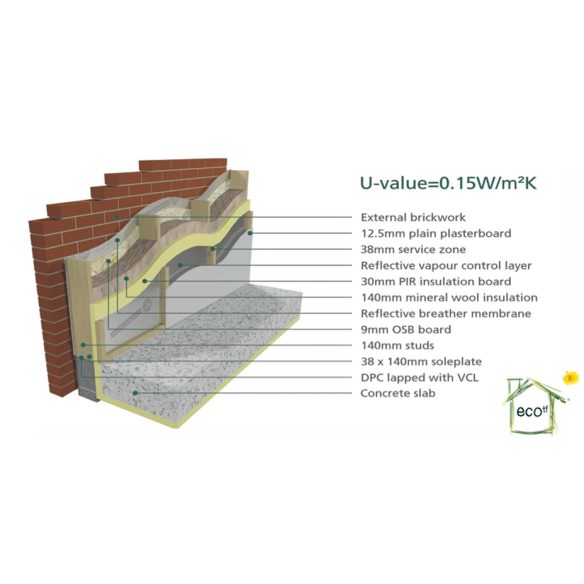

Deeside Timberframe offers industry-leading wall systems, and strives to exceed quality standards with a focus on durability and sustainability in everything we do. Flexibility of product and specification offering is central to our business, providing clients with solutions to meet their requirements. All products are manufactured offsite in factory-controlled conditions, which provides benefits such as consistency of quality and speed of construction.

Find the Right Wall System for You

At Deeside Timberframe, we understand that every project has unique requirements. Whether you’re considering a timber frame open panel wall system or a closed panel system, our dedicated team of specialists is here to guide you. Unsure about which wall system suits your needs? We’re committed to assisting you at every stage, ensuring you select the best wall systems tailored to your specific needs.

Let us be your trusted partner in finding the perfect solution.

Make an Enquiry

Need more information about our systems, or would like to speak to a member of our team?

Enquire NowBuild Systems

Sectors

Commercial

Offering accelerated, safe, and cost-efficient construction solutions for commercial clients.

Social Housing

Sustainably accelerating the construction of social housing without compromising on quality or safety.

Private Developers

Providing private housing developers with exceptional timber frame structures through offsite manufacturing.

Self-Builders

Empowering self-builders with high-quality, sustainable construction methods and unparalleled personal service.